The United States faces a critical technology commercialization gap—bridging the divide between prototype development and high-rate manufacturing of advanced aerospace composites. With the U.S. Air Force expecting to procure over 2,500 Collaborative Combat Aircraft (CCAs) by 2035 and commercial aerospace production requiring up to 100 aircraft per month, the need for rapid, efficient, and scalable composite manufacturing has never been greater.

The American Aerospace Materials Manufacturing Center (AAMMC) was created to close this gap. Our mission is to enable market-disrupting, high-rate production of large, complex aerospace structures that strengthen American self-sufficiency and leadership in both defense and commercial aviation.

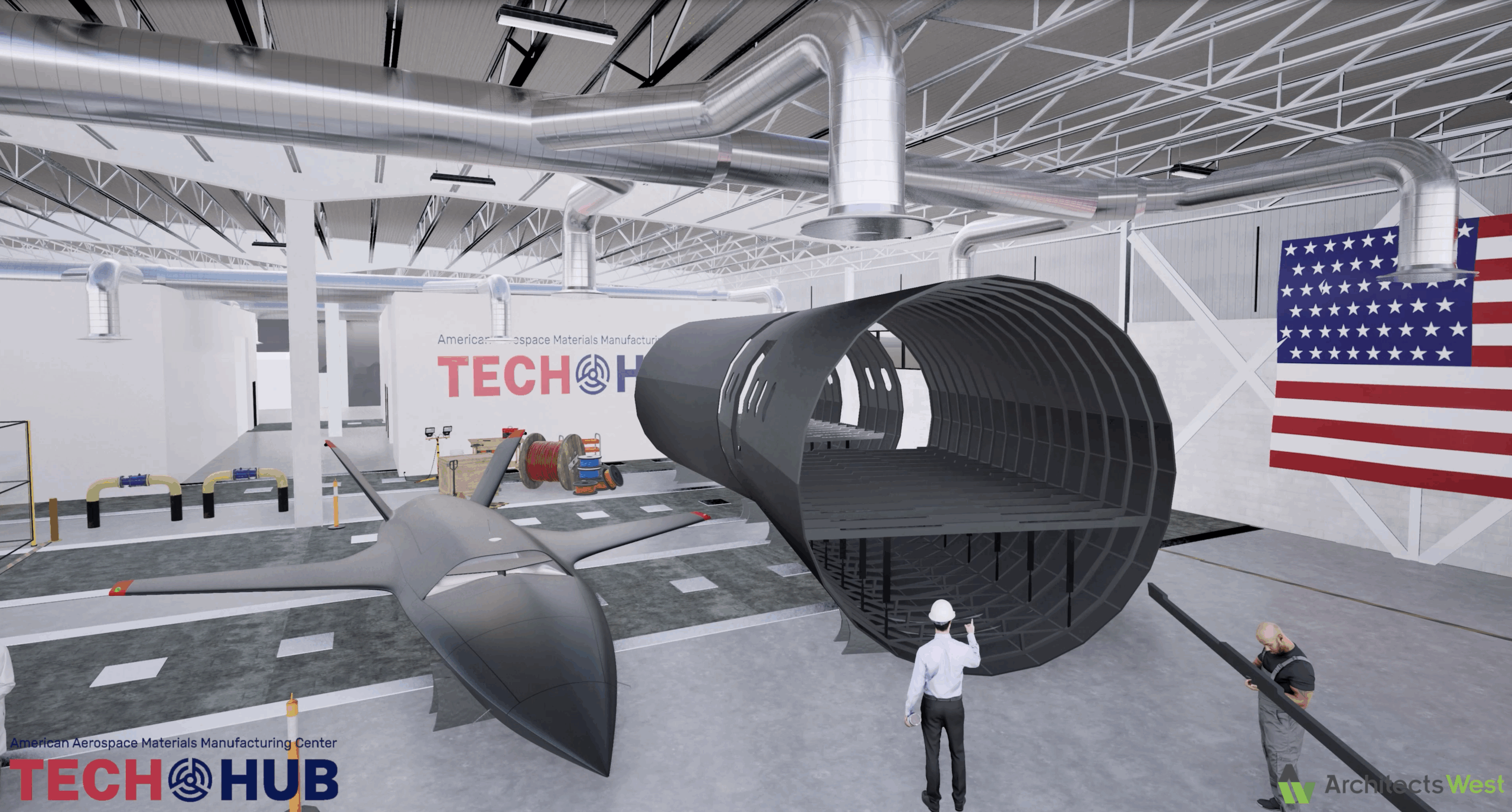

Our facility will house the largest advanced composites equipment in the world, including a 5,000-ton press, the largest of its kind, enabling high-pressure forming of fuselage frames, wings, ribs, and beams. This technology ensures exceptional dimensional accuracy, repeatability, and weight savings for critical structural components—delivering both speed and strength at scale.

Our Automated Fiber Placement (AFP) systems will further advance manufacturing precision and efficiency, producing massive aircraft panels and structures with optimized fiber orientation and minimal waste. Together, these technologies represent the future of American aerospace production—fast, repeatable, and globally competitive.

Beyond manufacturing, the AAMMC also serves as an industry-led hub for technical education, helping up-skill today’s workforce and train the next generation of advanced manufacturing professionals. We aim to align industry, investors, and education partners to build resilient domestic supply chains and keep our expertise—and innovation—American-owned.

This Tech Hub Flythrough, designed and produced by Architects West, captures the spirit of innovation, precision, and possibility that defines the AAMMC. We’re proud to share this vision of what’s to come—where technology, talent, and tenacity converge to redefine the future of aerospace manufacturing.