In a significant advancement, the American Aerospace Materials Manufacturing Center (AAMMC) has marked another milestone in its journey towards innovation and development. Recognized in October as a Regional Technology and Innovations Hub by the Economic Development Administration (EDA), the AAMMC has now taken a bold step forward by submitting a Phase 2 application for a substantial $80 million, $72 million grant plus $8 million match. This grant aims to further develop the Hub, aligning with the soaring demand for over 40,000 new aircraft over the next two decades—a demand that places immense pressure on the existing supply chain.

This initiative is timely and crucial, offering American suppliers a golden opportunity to meet the rising need for sustainable, lightweight aerostructures in both the defense and commercial sectors. The proposed Testbed and Training Center by AAMMC is poised to set a new industry standard. Unlike traditional production facilities, this center is designed for the full-scale fabrication of product certifications, equipped with cutting-edge technology and tooling unmatched anywhere in the world. The center’s establishment is a strategic move to boost the capabilities of new American aerospace suppliers, aiming to elevate the nation’s position to a global leadership role in aerospace.

The past four months have been marked by extraordinary effort and collaboration. The application represents the culmination of countless hours of work—beyond daily responsibilities—by a dedicated consortium of professionals. Their commitment reflects the collective ambition to drive significant advancements in aerospace, economic growth, and workforce development, particularly in the Inland Northwest and beyond.

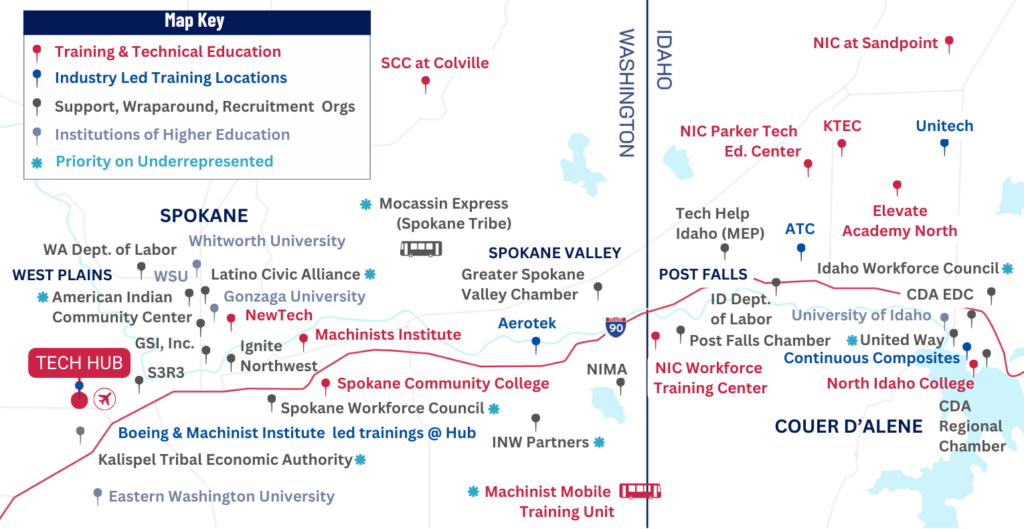

The current focus is on the collaborative strength across the region, depicted in the above regional network map, showcasing the united drive for workforce and economic improvement in the Inland Northwest. As the AAMMC awaits the outcome of its application, the excitement for the potential benefits this project could bring to the aerospace sector and the broader economy is palpable. This initiative stands as a powerful example of what can be achieved through collaboration and vision. The AAMMC extends its gratitude for the ongoing support and commitment from all stakeholders involved in this transformative project.

Updates on this ambitious endeavor will be shared as they become available, underscoring the collective journey towards redefining aerospace innovation and leadership.

An overview of the AAMMC, it’s project goals, members, and key components can be downloaded by clicking here.

Machinists Institute, and the Spokane Workforce Council | Fox 28

In an interview with Fox 28, Jason Trosine from the Machinists Institute highlighted their commitment to training the current and future workforce in aerospace manufacturing and automotive machinists. Aligning their mission with the goals of the hub, the Machinists are interested in creating training spaces and enacting clean economy initiatives. Their North Idaho training facility and mobile training unit enable flexible training opportunities, and showcase a unique opportunity to support workforce development and sustainable practices in the region.

Spokane Workforce Development Council and NIMA Alliance | Fox 28

Mark Mattke CEO of the Spokane Workforce Development Council and Mark Norton from the Northwest I-90 Manufacturing Alliance discussed the strong existing manufacturing base in Spokane and how the AAMMC Tech Hub application can help strengthen the manufacturing and job opportunities in the region moving forward.

ATC Manufacturing & Lakeside Companies on NW Aerospace News Live

ATC Manufacturing representative David Leach, and Lakeside Companies representative Maria Lusardi, also discussed the goals and nuances of the tech hub. David Leach, ATC manufactures aerospace components using highly reinforced thermoplastic composites. While these thermoplastic composites have become established in many aircraft parts, the next step forward is to apply these materials into a larger scale on the next generation of aircraft.